Granite Surface Plate Calibration Equipment

Gray granite inserts inspection measuring equipment supplies lap conditioner lapping lapping plate 17025 calibration.

Granite surface plate calibration equipment. Excluding those contained in other quality standards such as iso iec 17025 the minimum fed. Our reports contain a significant amount of both critical and pertinent information. There are pink gray and black granites that are excellent for surface plates as well as pink gray and black granites that are totally unsuitable for precision applications. Our granite surface plates are manufactured in three ledge types as well as standard sizes and grades.

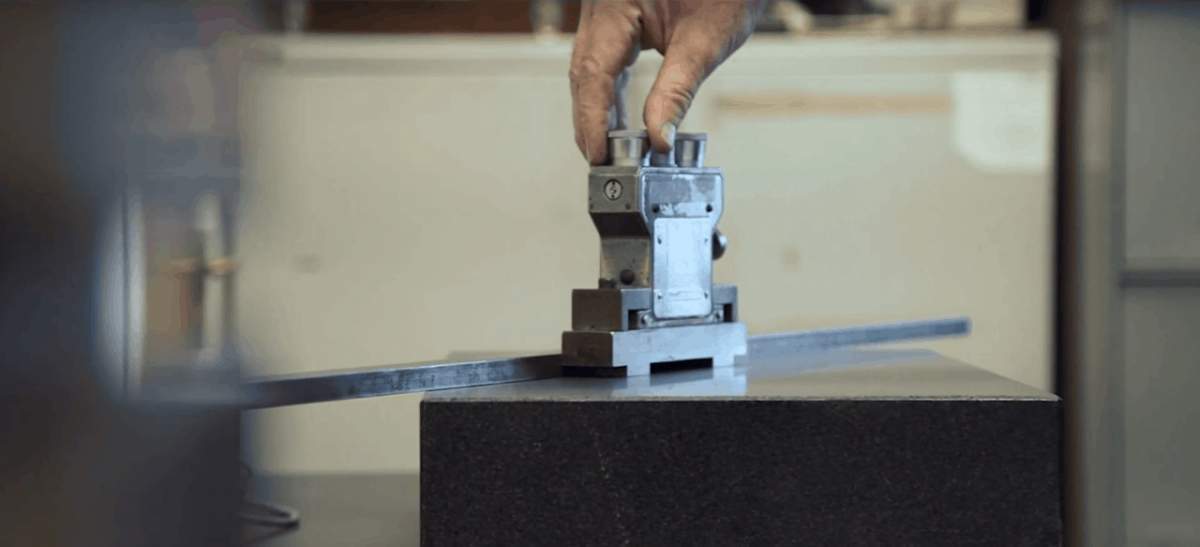

We also offer granite surface plate resurfacing if needed with a relap to bring surface plate back into specification. Our accredited granite surface plate calibration covers grades aa a and b for repeatability at 0 002 inches and flatness up to 60 inches in diagonal length. Immediately dry the cleaner off the surface plate with a dry cloth. Place a repeat measuring gauge on the center of the granite surface plate.

Because every linear measurement depends on an accurate reference surface from which final dimensions are taken surface plates provide the best reference plane for work inspection and layout prior to machining. For each surface plate repair and calibration we provide detailed professional reports. Your granite surface plate is one of your most important parts of. We can certify your surface plate to grade aa laboratory grade grade a inspection grade or grade b toolroom grade.

Requires most of the information we provided. Each type of metrology equipment requires a base plate to measure from. A granite surface table would be used as a base for a digital height gauge and larger machines such as a bridge cmm have a granite surface plate as part of the machine. For many shops inspection rooms and laboratories precision granite surface plates are relied on as the basis for accurate measurement.

All calibrations performed in the field are traceable to nist the national institute of standard and technology and are performed in accordance with documented and controlled procedures. Granite surface plate maintenance. Your granite surface plate granite block granite table is the foundation of all accurate measurements optimal calibration has the ability to achieve extremely tight tolerances to ensure that your are getting the most precise measurements possible. Clean the granite surface plate prior to calibration.

In general granite s color is directly related to the presence or absence of minerals which may have no bearing on the qualities that make good surface plate material.